Construction does not only involve people but also machinery. There is also a collaboration between a person and a machine for it to work efficiently. A person cannot accomplish a hard construction task like drilling on the wall without using a drilling device. It’s the same in the case of a drilling device. It cannot work alone without the intervention of a construction worker who will work on the logistics and operate the device, as well.

Machinery and equipment vary in size, style, function, and level of performance. A hand-held saw cannot handle the jobs of a heavy loader saw. Conversely, the heavy loader saw cannot cut lightweight materials because its high level of performance can damage the lightweight material.

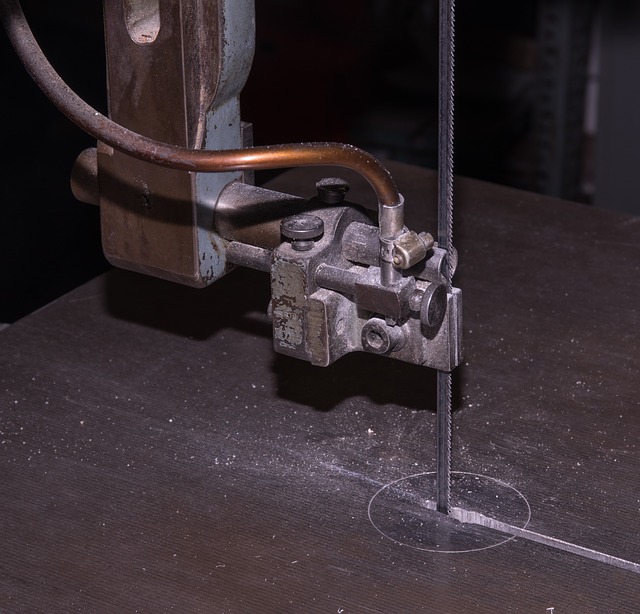

When it comes to high-precision cutting, you need to choose the right custom bandsaw blades for production machining. Choosing the right cutting tool does not only mean that you bought it at a reasonable price; functionality matters most. Different cutting or holing jobs require different tools. You need to find out the requirements of the job before you can decide on the kind of blade you will need.

Blade Requirements

Compare the kind of blade versus the kind of material

If you are cutting steel or stone tiles, you need heavier equipment. Blades that do not have enough thickness and cutting speed tend to break apart if you use them on strong materials.

Determine the level of difficulty of the job

Cutting is not only as easy as paper cutting. You need to determine the quantity and the maximum capacity of your blades and cutting tools before you proceed on a cutting job.

Availability of replacement

Make sure that your cutting tools have parts that can be replaced based on what is available at the hardware stores, in case any problem happens.

The Segmented Rim

The segmented rim is one of the best blades that you can consider because it can cut even the toughest materials such the concrete pavers, bricks, concretes, blocks, hard concrete and limestone. This blade is usually called a dry cutting blade because of the application where it can be used. This is ideal for dry use because the segments are located at the edge of the blade. This allows the air to flow and cool the core of the blade. If there is no water available, this could be the option for you.

The Continuous Rim

The continuous rim is called the wet cut blade. There are some benefits that you can enjoy when you are using water to cut different products. The water could best to cool the blade and make it more useful for a longer period of time. It helps to release all the debris and reduce the friction on the cutting zone. It also helps to reduce the formation of dust.

Material Cutting Considerations

There are different kinds of blades that come in various shapes and serve multiple purposes. There is a circular type that is widely used, a gang saw or one with a long steel plate used for blocks, a closed steel band saw, and many others. There are those that are used for concrete, bricks, glass, stones, and many other things.

Blade Geometry

Newer innovations in blade construction mean that there is more room for improvement when it comes to tooth geometry. For example, the recently introduced band saw blade with a tooth design provides a bigger tooth cross-section with a lot of benefits. These include low noise and vibration levels, faster chip removal, easier elimination of tooth strippage, and a better cutting surface. The characteristics of the material have to be considered, too, so you can choose the right abrasive needed on band saw blades.