In the fast-paced world of manufacturing, where precision and efficiency are paramount, the integration of collaborative robots – commonly known as cobots – has revolutionized the landscape of inspection and quality assurance. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside humans, enhancing workflows and improving operational standards. This article explores how cobot arms are streamlining inspection and quality assurance processes, making them more efficient, accurate, and safe.

The Role of Cobot Arms in Modern Manufacturing

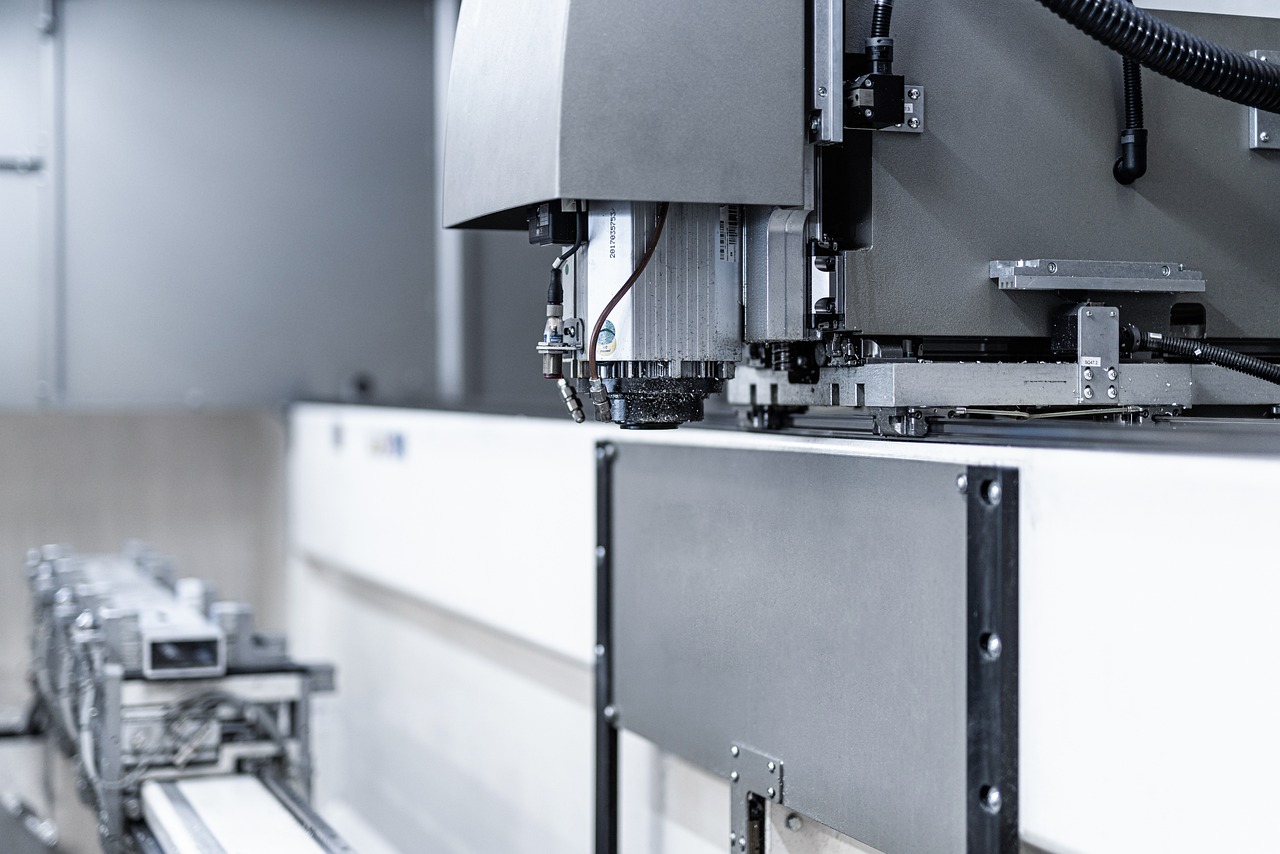

Cobots have transformed manufacturing practices by automating tasks that were once manual and time-consuming. They are designed with flexibility in mind, enabling easy integration into existing production lines without significant changes to infrastructure.

Historically, the automation landscape has been dominated by heavy-duty robots that require extensive safety barriers and dedicated workspaces. In contrast, cobots are engineered for collaboration, featuring advanced sensors and safety mechanisms that allow them to operate safely alongside human workers. This adaptability has made them a popular choice across various industries, from automotive to electronics.

Enhancing Inspection Processes with Cobot Arms

One of the most significant advantages of using cobot arms in inspection is their ability to automate repetitive tasks, such as visual inspections and measurements. Tasks that require constant attention can lead to human fatigue and potential errors over time. By automating these processes, cobots ensure that inspections are carried out consistently and efficiently.

For example, a manufacturing facility producing electronic components can utilize cobots equipped with high-resolution cameras to conduct visual inspections for defects on production lines. These systems can operate continuously, significantly increasing throughput without sacrificing quality.

Increased Speed and Efficiency

The speed at which cobots can perform inspections surpasses that of human workers. They can execute repetitive tasks at a consistent pace, leading to higher efficiency on the production line.

For instance, a case study involving a packaging facility showed that integrating cobots for quality checks reduced the time taken for inspections by nearly 50%. This improvement not only boosted production rates but also allowed human workers to focus on more complex tasks that require critical thinking and creativity.

Accuracy and Precision in Quality Assurance

When it comes to quality assurance, consistency is key. Cobots are programmed to perform specific tasks with precision, ensuring that each inspection adheres to the same standards. This level of consistency is difficult to achieve with human operators, who may vary in performance due to fatigue or distraction.

Research has shown that cobots can improve inspection accuracy by up to 30% compared to manual inspections. Their ability to eliminate human error significantly enhances the reliability of quality assurance processes.

Error Reduction

Cobots not only improve the accuracy of inspections but also contribute to a notable reduction in error rates. The implementation of automated inspection systems leads to fewer defects escaping into the market, which can save companies from costly recalls and damage to their reputation.

The advanced sensor technologies employed in cobots allow for detailed inspections, capable of detecting even the most minor defects that human inspectors might overlook. As a result, manufacturers can maintain higher quality standards, ensuring customer satisfaction and compliance with industry regulations.

Enhanced Testing Capabilities

Modern cobots come equipped with advanced testing capabilities, including vision systems that can analyze dimensions, color, and surface defects. These features allow for comprehensive inspections that go beyond what traditional methods can achieve.

For instance, a facility producing automotive parts can utilize cobots to perform precise measurements and checks against specifications, ensuring that every component meets stringent industry standards. This level of detail is essential for industries where safety is critical.

Safety and Ergonomics in the Workplace

The collaborative nature of cobots contributes significantly to workplace safety. Unlike traditional robots that require dedicated areas and safety barriers, cobots can work side-by-side with human operators. They are designed with features such as force-limiting technology, which allows them to sense their environment and stop automatically if they come into contact with a human.

This collaborative approach not only enhances safety but also fosters a more productive work environment. Employees can focus on higher-value tasks while leaving repetitive or hazardous inspections to the cobots.

Reducing Human Risk Factors

By taking over repetitive inspection tasks, cobots help reduce the risk of injuries associated with manual inspections. Workers no longer need to perform tasks that involve repetitive motions or awkward postures, which can lead to musculoskeletal disorders over time.

Furthermore, by reducing the human workload, cobots minimize the chances of accidents resulting from fatigue or distractions. This shift leads to a safer workplace overall.

Ergonomic Benefits

The introduction of cobots also promotes ergonomic benefits in the workplace. Workers can shift their focus from monotonous tasks to more engaging activities that require cognitive skills. This change not only boosts employee morale but also enhances productivity and job satisfaction.

Conclusion

Cobot arms are fundamentally changing the landscape of inspection and quality assurance in manufacturing. By enhancing efficiency, accuracy, and safety, these collaborative robots enable companies to meet rising quality standards while optimizing their operations. As cobot technology continues to advance, the benefits will only multiply, making them an invaluable asset for any forward-thinking manufacturer. For those looking to explore cobot solutions, UR robots offer a range of options that can seamlessly integrate into existing workflows, paving the way for a more efficient and quality-driven future.